-

Alfred...Malı aldık, her şey yolunda gitti. Mükemmel ambalaj, iyi ürün kalitesi, iyi fiyat - memnunuz.

Alfred...Malı aldık, her şey yolunda gitti. Mükemmel ambalaj, iyi ürün kalitesi, iyi fiyat - memnunuz. -

Mayıs...Ürün kalitesi çok iyi, beklentilerimi aştı, gerçek kullanım tüm ihtiyaçlarımı karşıladı, tekrar satın alacağız.

Mayıs...Ürün kalitesi çok iyi, beklentilerimi aştı, gerçek kullanım tüm ihtiyaçlarımı karşıladı, tekrar satın alacağız. -

Matthew...Joy'dan düşük genleşmeli alaşım aldım. O çok sorumluluk sahibi bir hanımefendi. Huona'nın ürünlerinin kalitesi oldukça iyi.

Matthew...Joy'dan düşük genleşmeli alaşım aldım. O çok sorumluluk sahibi bir hanımefendi. Huona'nın ürünlerinin kalitesi oldukça iyi.

Inconel 625 Kaynak Teli (Ni-Cr-Mo Süperalaşım) Yüksek Sıcaklık ve Korozyona Dayanıklı Kaynak İçin ERNiCrMo-3 Dolgu Metali

| İşlem uyumluluğu | MIG / TIG / SAW / Ark Sprey / Alev Sprey | Çalışma sıcaklığı | 1000 ° C'ye kadar |

|---|---|---|---|

| Mekanik güç | Yüksek (Yük ve termal çevrime uygun) | Korozyon direnci | Mükemmel, dahil. Klorürler ve Oksitleyici kimyasallar |

| Durum | Makara Teli / Çubuk Formu | Makara Ağırlığı | 1kg / 5kg / 15kg / Özel |

| Tedarik Kapasitesi | 40–60 ton/ay | Kurşun zamanı | 3–7 gün (standart boyutlar) |

| Vurgulamak | Inconel 625 kaynak tel,Ni-Cr-Mo süperalaşım dolgu metali,yüksek sıcaklığa dayanıklı korozyona dayanıklı kaynak teli |

||

Inconel 625 Kaynak Teli (Ni-Cr-Mo Süperalaşım)

Yüksek Sıcaklık ve Korozyona Dayanıklı Kaynak İçin ERNiCrMo-3 Dolgu Metali

Mevcut Çaplar: 1.0 mm / 1.2 mm / 1.6 mm

Ürüne Genel Bakış

Inconel 625 kaynak teli (ERNiCrMo-3) nikel-krom-molibden-niobyum süperalaşım dolgu metalidir.

Yüksek sıcaklık oksidasyonuna, deniz suyu korozyonuna, klorür çukurlaşmasına, çatlak korozyonuna ve gerilme korozyon çatlamasına karşı olağanüstü direnç sağlar.

Genellikle Ni bazlı alaşımları, paslanmaz çelikleri ve farklı metalleri birleştirmek ve kaplamak için kullanılır kimyasal işleme, denizcilik, havacılık, enerji ve açık deniz ekipmanlarında

.

| Kimyasal Bileşim (Tipik) | Element |

|---|---|

| İçerik (%) | Nikel (Ni) |

| Denge | Krom (Cr) |

| 20.0 – 23.0 | Molibden (Mo) |

| 8.0 – 10.0 | Niobyum + Tantal (Nb+Ta) |

| 3.15 – 4.15 | Demir (Fe) |

| ≤ 5.0 | Diğerleri |

EserŞunlara Uygundur:

ASTM / AWS ERNiCrMo-3 (Inconel 625)

-

Temel ÖzelliklerMükemmel korozyon direnci

-

deniz suyunda, asitlerde ve klorür ortamlarındaYüksek sıcaklık dayanımı ve oksidasyon kararlılığı

-

~980°C'ye kadarÇatlaklara dayanıklı kaynaklar

-

güçlü metalurjik bağ ileŞunlar için uygundur:

-

farklı metal kaynağı

(Ni-bazlı ↔ paslanmaz çelik)

-

Pürüzsüz besleme ve kararlı ark özellikleriUygulama Alanları

-

Kimya ve Petrokimya: Isı eşanjörleri, reaktörler, boru hatları

-

Denizcilik ve Açık Deniz: Pompa milleri, deniz suyu sistemi bileşenleri

-

Havacılık: Motor bileşenleri, egzoz sistemleri

-

Nükleer ve Enerji Üretimi: Kazan boruları, kaplama koruması

Onarım ve Kaplama Kaplama:

| Aşınma + korozyon koruyucu yüzey kaplama | Teknik Özellikler |

|---|---|

| Öğe | Değer |

| Ürün Adı | Inconel 625 Kaynak Teli |

| AWS Sınıfı | ERNiCrMo-3 |

| Malzeme Türü | Ni-Cr-Mo-Nb Süperalaşım |

| Ana Çaplar (主推) | 1.0 mm / 1.2 mm / 1.6 mm |

| Diğer Çaplar | İsteğe bağlı olarak 2.0 / 2.4 / 3.2 mm |

| Form | Makara / Çubuk |

| Kaynak İşlemleri | TIG / MIG / SAW / Ark Püskürtme / Alev Püskürtme |

| Servis Sıcaklığı | ~980°C'ye kadar |

Kaplama Görünümü (Püskürtülmüş)

-

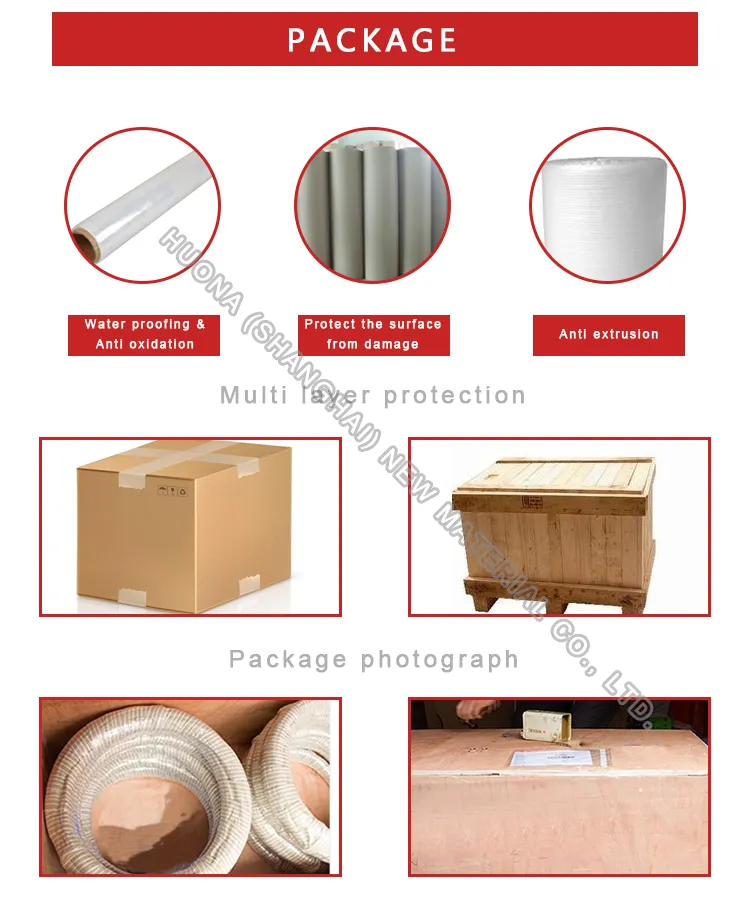

Yoğun gümüş-gri metalik kaplamaAmbalaj ve Tedarik

-

Makara: 1kg / 5kg / 15kg / 20kg

-

Çubuklar: plastik tüp başına 5kgOEM &

-

özel etiket

markası mevcutturİhracat palet ambalajı mevcuttur

Stok: Düzenli envanter mevcuttur

Kapasite: ~40–60 ton/ay

Teslim Süresi:

| 3–7 gün (standart) | 10–15 gün (özel) | Özel Nitelikler (可直接复制到环球广贸 / 阿里后台) |

|---|---|

| Öznitelik Adı | Öznitelik Değeri |

| Ürün Adı | Inconel 625 Kaynak Teli |

| AWS Sınıfı | ERNiCrMo-3 |

| Alaşım Türü | Ni-Cr-Mo-Nb Süperalaşım |

| Ana Çaplar | 1.0 mm / 1.2 mm / 1.6 mm |

| Tel Formu | Makara / Çubuk |

| Kaynak Yöntemleri | TIG / MIG / SAW / Ark Püskürtme / Alev Püskürtme |

| Sıcaklık Dayanımı | ~980°C'ye kadar |

| Korozyon Direnci | Deniz suyunda ve klorür ortamlarında mükemmel |

| Ambalaj | Makara / Tüp / Kutu / Palet |

| Aylık Tedarik | 40–60 ton |

Etiketler:

Etiketler:

Termal yay püskürtme tel

Nikel kromlu tel

ASTM Alaşımlı Tel